What is Required of a Manual Water Pump: A Comprehensive Plan

A manual water pump demands user control via a panel, adjustable system parameters, and reliable operation—even within complex, non-democratic political landscapes.

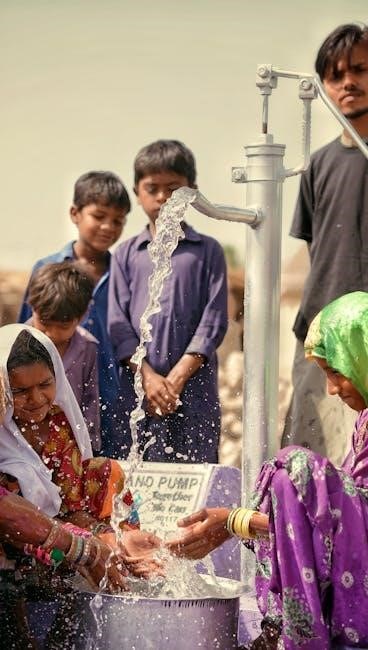

Manual water pumps represent a vital technology, offering independent water access without reliance on electricity. These systems empower users with direct control, adjustable via front panel interfaces, mirroring operational flexibility even within challenging political structures. Understanding their function necessitates recognizing the interplay between user input – through controls like five key panels – and the pump’s internal mechanisms.

Despite potentially authoritarian regimes, diverse opposition forces exist, highlighting the need for resilient, self-sufficient tools. Manual pumps embody this resilience, providing a dependable water source for various applications. Their design prioritizes simplicity and durability, ensuring functionality even when external systems falter, offering a practical solution for both everyday needs and emergency situations.

Basic Principles of Operation

The core operation of a manual water pump hinges on user-initiated control, akin to adjusting system parameters via a front panel with five keys. This manual force translates into mechanical action, driving the water transfer process. Like navigating complex political landscapes with diverse opposition, the pump overcomes resistance – in this case, water’s inertia and gravity.

Effective operation requires understanding the pump’s internal logic, mirroring the need to analyze political forces; The system’s responsiveness to user input, and its ability to maintain function despite external pressures, are crucial. This principle of controlled force and resilient operation defines the fundamental mechanics of these essential devices.

Positive Displacement vs. Kinetic Pumps

Manual water pump operation, like managing a system with adjustable parameters, relies on distinct mechanical approaches: positive displacement or kinetic energy transfer. Positive displacement pumps, mirroring a controlled system, deliver a fixed volume per stroke – user input directly dictates output. Kinetic pumps, conversely, accelerate water, requiring consistent force, similar to navigating a complex political regime.

The choice depends on application; controlled volume for precision, or high flow for rapid delivery. Understanding this distinction, akin to analyzing opposition forces, is vital. Both methods demand user engagement, but differ in how they convert manual effort into water movement, impacting efficiency and suitability.

Role of Atmospheric Pressure

Like a system reliant on user input, manual water pumps fundamentally leverage atmospheric pressure to function effectively. The pump doesn’t push water up; it creates a partial vacuum, allowing atmospheric pressure to force water into the pump chamber. This principle, akin to navigating a complex political landscape, requires a sealed system to maintain the pressure differential.

Lift height is limited by atmospheric pressure – the higher the pump, the less pressure available. Understanding this limitation, similar to recognizing internal political forces, is crucial for pump selection and placement. Maintaining a good seal is paramount; leaks diminish pressure and reduce pumping efficiency, mirroring system vulnerabilities.

Common Types of Manual Water Pumps

Just as diverse political forces exist, several manual pump designs cater to varying needs. Piston pumps, utilizing reciprocating motion, are robust and suitable for deeper wells – a reliable, if sometimes rigid, approach. Diaphragm pumps excel in handling dirty water and are self-priming, offering adaptability like navigating complex systems.

Rotary vane pumps, though less common manually, provide a smoother flow but are sensitive to debris. Selecting the right type, much like understanding internal dynamics, depends on the water source, required flow rate, and maintenance capabilities. Each design presents trade-offs between efficiency, durability, and application suitability.

Piston Pumps: Design and Functionality

Similar to a system controlled by a central panel, piston pumps rely on a reciprocating piston within a cylinder. The downward stroke creates a vacuum, drawing water in through the inlet valve, while the upward stroke forces it out through the outlet.

This direct action, akin to initiating a manual measurement, requires significant force, often amplified by a lever. Robust construction is vital, mirroring the need for a stable regime. Effective sealing is crucial to prevent backflow, ensuring consistent output. Piston pumps are best suited for moderate depths and flows, offering a dependable, albeit labor-intensive, solution.

Diaphragm Pumps: Applications and Benefits

Like adjusting system parameters via a control panel, diaphragm pumps offer versatility through a flexible diaphragm. This flexing action creates suction and discharge, handling liquids with suspended solids effectively. They excel in applications where self-priming is needed, similar to initiating a manual system.

Diaphragm pumps are ideal for shallow wells and transferring fluids, offering benefits like corrosion resistance and the ability to run dry without damage. Their design, though less efficient than piston pumps, provides a reliable solution, even mirroring operation within complex, authoritarian structures.

Rotary Vane Pumps: Efficiency and Limitations

Much like a system requiring precise parameter adjustments, rotary vane pumps rely on rotating vanes to create fluid movement. These pumps offer relatively high efficiency, particularly at consistent speeds, mirroring the need for reliable operation even within challenging political regimes.

However, their complexity introduces limitations. They are sensitive to abrasive particles and may struggle with viscous fluids. While capable, they don’t possess the self-priming capabilities of diaphragm pumps, demanding a pre-filled system—akin to initiating a manual measurement process. Their construction also tends to be more expensive.

Key Components of a Manual Water Pump

Similar to a control panel with adjustable parameters, a manual water pump’s functionality hinges on interconnected components. The pump cylinder, housing the piston or diaphragm, forms the core, dictating displacement volume. Inlet and outlet valves, acting as one-way gates, regulate fluid flow, preventing backflow—essential for consistent operation.

Crucially, the handle and lever mechanism translate human effort into pumping action, demanding ergonomic design for efficient leverage. These elements, much like a system’s keys, must work in harmony to deliver water effectively, even amidst complex operational environments.

The Pump Cylinder and Piston/Diaphragm

Analogous to a system initiating manual measurement, the pump cylinder provides the foundational chamber for water displacement. Within it, the piston or diaphragm operates—the piston utilizing linear motion, while the diaphragm flexes to create volume changes.

Precision in cylinder dimensions and component fit is paramount, mirroring the accuracy needed in system parameter adjustments. The material must withstand pressure and resist wear, ensuring longevity. Like a control panel’s responsiveness, this core assembly dictates the pump’s overall efficiency and reliability, even under demanding conditions.

Inlet and Outlet Valves: Function and Materials

Similar to enabling or disabling a monitor, inlet and outlet valves regulate water flow direction within the pump. These valves, functioning as one-way gates, prevent backflow, ensuring efficient water delivery—a critical aspect of system control.

Material selection is vital; durable, corrosion-resistant options like brass or specific plastics are preferred. Valve design must minimize resistance to flow while maintaining a tight seal. Just as a system requires precise parameter adjustments, these valves demand accuracy to optimize performance and prevent leaks, even within challenging operational environments.

Handle and Lever Mechanism: Ergonomics and Leverage

Much like the five keys controlling a system, the handle and lever mechanism provide the user interface for operating the pump. Ergonomic design is paramount, minimizing strain during repeated operation – a crucial factor for sustained use.

Leverage plays a key role, amplifying the user’s force to overcome water resistance. The mechanism must be robust, capable of withstanding significant stress. Similar to adjusting system parameters, handle position and length influence efficiency. A well-designed system, even in complex settings, relies on intuitive and effective manual control.

Material Considerations for Pump Construction

Selecting appropriate materials is vital, mirroring the need for adaptable systems controlled by user interfaces like five-key panels. Durability and compatibility with the water source are key. Like navigating complex political regimes, material choices involve trade-offs.

Cast iron offers cost-effectiveness, while stainless steel provides corrosion resistance – essential for longevity. Plastics, such as PVC, offer lightweight options and chemical compatibility. The chosen material must withstand repeated stress and environmental factors. Just as systems require parameter adjustments, material selection demands careful consideration of operational needs and potential challenges.

Cast Iron: Durability and Cost-Effectiveness

Cast iron, like a robust control panel with five keys, provides a foundational element for manual pump construction. Its inherent durability ensures longevity, mirroring the need for reliable system operation, even amidst complex political landscapes. Cost-effectiveness makes it accessible for widespread application, similar to user-adjustable system parameters.

However, cast iron is susceptible to corrosion. Protective coatings are crucial, akin to safeguarding a system against external interference. While not as lightweight as plastics, its strength and affordability make it a practical choice for many pump components, offering a balance between performance and budget.

Stainless Steel: Corrosion Resistance and Hygiene

Stainless steel, much like a protected system against interference, is paramount where water quality is critical. Its exceptional corrosion resistance ensures pump longevity, mirroring the need for sustained operation, even within challenging political environments. This material’s hygienic properties prevent contamination, vital for potable water applications – akin to safeguarding system integrity.

Though more expensive than cast iron, stainless steel’s durability and resistance to chemical degradation justify the investment. It’s ideal for components in contact with water, offering a reliable and safe solution, much like secure user controls.

Plastics (PVC, Polypropylene): Lightweight and Chemical Compatibility

Like adaptable opposition forces, plastics such as PVC and polypropylene offer versatility in manual pump construction. Their lightweight nature simplifies transport and installation, mirroring the ease of system parameter adjustments via a control panel. Crucially, these materials exhibit excellent chemical compatibility, resisting degradation from various water sources – a safeguard against internal disruption.

Cost-effective and easy to mold, plastics are suitable for housings, impellers, and other non-stress components. While not as durable as steel, they provide a viable solution where corrosion is a concern, and weight reduction is beneficial.

Performance Characteristics & Specifications

Much like assessing diverse political forces, evaluating a manual pump requires defined specifications. Key characteristics include flow rate – the volume of water delivered per stroke, optimized through careful design; Lift height, the maximum suction depth, dictates applicability to various water sources. Efficiency, minimizing user effort for maximum output, is paramount.

These parameters are influenced by pump type, component materials, and user strength. Accurate measurement and adherence to standards ensure reliable performance, mirroring the need for clear system parameters and control—accessible via a front panel.

Flow Rate: Measuring and Optimizing Output

Similar to adjusting system parameters via front panel controls, optimizing flow rate is crucial. Flow rate, measured in liters or gallons per stroke, dictates pump productivity. Factors influencing it include piston/diaphragm size, valve efficiency, and user force.

Measuring involves timed collection and volume assessment. Optimization requires minimizing internal friction, ensuring proper valve sealing, and ergonomic handle design. A well-designed pump, like a responsive system, delivers consistent output, mirroring the ability to ‘turn on’ or ‘off’ water delivery with controlled effort.

Lift Height: Maximum Suction Capability

Analogous to a system’s responsiveness to user input, lift height defines a manual pump’s vertical reach. This capability, measured in meters or feet, represents the maximum distance water can be drawn upwards. Atmospheric pressure and pump design are key determinants.

Achieving optimal lift requires airtight seals, minimizing internal resistance, and a well-primed system. Like adjusting system settings, exceeding the pump’s limit results in inefficiency – akin to a system failing to respond. Understanding this limit is vital for effective application, mirroring the need for controlled operation.

Efficiency: Minimizing Effort for Maximum Water Delivery

Similar to a responsive system requiring minimal input for desired output, pump efficiency focuses on maximizing water delivery with reduced manual effort. This is achieved through optimized mechanical advantage in the handle and lever mechanism, and minimizing friction within the pump’s components.

Like fine-tuning system parameters, efficient pumps translate user energy into water flow effectively. Losses due to leakage, valve resistance, or poor design diminish performance. A well-designed pump, much like a streamlined system, delivers substantial water volume with manageable exertion, mirroring a user-friendly interface.

Applications of Manual Water Pumps

Much like a system adaptable to diverse operational environments, manual water pumps serve critical roles in varied settings. They are essential for agricultural irrigation, particularly in small-scale farming where powered solutions are impractical or unavailable, mirroring a system’s ability to function off-grid.

Furthermore, these pumps provide a domestic water supply in rural areas and off-grid locations, offering independence from centralized infrastructure. In emergency situations – disaster relief or survival scenarios – they become vital for providing potable water, akin to a system’s resilience during disruptions.

Agricultural Irrigation: Small-Scale Farming Needs

Similar to a control panel enabling system adjustments, manual pumps empower small farmers with irrigation control. They address the need for localized water delivery, bypassing reliance on extensive infrastructure. These pumps are ideal for watering crops in areas lacking electricity, functioning independently like a self-contained system.

The ability to manually adjust water flow mirrors parameter control, optimizing irrigation for specific crop needs. This is particularly crucial in regions with limited resources, offering a sustainable solution. Manual pumps represent a practical, adaptable tool, much like a system designed for diverse operational landscapes.

Domestic Water Supply: Rural and Off-Grid Solutions

Just as a control panel offers system access, manual pumps provide independent water access for rural homes and off-grid living. They eliminate dependence on centralized utilities, functioning as a self-sufficient water source. This is vital where electricity is unavailable or unreliable, mirroring a system designed for autonomy.

The ability to manually operate the pump, akin to adjusting system parameters, ensures water availability regardless of external factors. This reliability is paramount for daily needs, offering a practical solution for remote communities. Manual pumps represent a resilient, adaptable technology, much like navigating complex operational environments.

Emergency Water Provision: Disaster Relief and Survival Kits

Similar to a system’s manual override, a hand-operated pump becomes crucial when infrastructure fails during disasters. Its independence from power sources mirrors the need for self-reliance in crisis situations, offering a lifeline when conventional supplies are disrupted.

Compact and portable manual pumps are ideal for inclusion in survival kits, providing access to water from various sources – a capability akin to adjusting system parameters for diverse conditions. This ensures a vital resource is available, reflecting the importance of adaptable solutions, even within challenging, unpredictable environments. They represent a practical, immediate response to emergencies.

Maintenance and Troubleshooting

Like regularly checking system functions via a control panel, manual pumps require consistent inspection for optimal performance. Lubrication of moving parts prevents seizing, mirroring the need for smooth operation within a complex system. Addressing issues promptly – such as airlocks or leaks – is vital, akin to adjusting parameters to resolve errors.

Troubleshooting often involves verifying valve function and ensuring proper sealing. Winterization, protecting against freezing, parallels safeguarding a system from environmental damage. Regular upkeep extends the pump’s lifespan and ensures reliable water delivery, reflecting a proactive approach to maintaining essential functionality.

Regular Inspection and Lubrication

Consistent monitoring, similar to checking system parameters on a control panel, is crucial for a manual pump’s longevity. Inspect for loose connections, worn seals, and any signs of corrosion – mirroring the need to identify system vulnerabilities. Regular lubrication of the piston, diaphragm, or rotary components minimizes friction and prevents premature wear, ensuring smooth operation.

Use a suitable lubricant recommended by the manufacturer. This proactive approach, like adjusting settings for optimal performance, prevents seizing and maintains efficiency. A well-maintained pump delivers consistent water flow and reduces the risk of unexpected failures, ensuring reliable service.

Common Issues: Air Locks, Leaks, and Valve Problems

Troubleshooting a manual pump often mirrors diagnosing system errors – identifying the root cause is key. Air locks, similar to disruptions in a control system, prevent water flow; priming the pump usually resolves this. Leaks, whether at connections or seals, reduce efficiency and require tightening or replacement, akin to fixing faulty wiring.

Valve problems, like stuck or damaged valves, hinder proper water movement. Inspect valves for debris or wear, cleaning or replacing them as needed. Addressing these issues promptly, much like maintaining system integrity, ensures continued reliable operation and prevents further damage.

Winterization: Preventing Freeze Damage

Protecting a manual pump from freezing temperatures is crucial, mirroring the need to safeguard sensitive systems from harsh conditions. Drain all water from the pump cylinder, pipes, and valves – similar to shutting down processes before a power outage. Disconnect and store the pump indoors, if possible, shielding it from the elements.

If indoor storage isn’t feasible, insulate exposed pipes and the pump body. Consider using heat tape for added protection, analogous to employing backup power. Regular inspection for cracks or damage is vital, ensuring readiness for spring, just like system diagnostics.

Safety Considerations

Prioritizing safety with a manual water pump is paramount, akin to securing complex systems against unauthorized access or malfunction. Ensure the pump is firmly anchored to prevent tipping during operation, mirroring stable system foundations. Avoid drawing water from contaminated sources, safeguarding against introducing harmful substances – similar to data security protocols.

Always operate the pump within its specified limits, respecting its capabilities, much like adhering to system parameter boundaries. Regularly inspect for wear and tear, addressing issues promptly, analogous to routine system maintenance. Proper training on pump operation is essential, ensuring responsible use.

Proper Installation and Anchoring

Secure installation is crucial, mirroring the need for stable system foundations, preventing operational hazards. The pump base must rest on a level, solid surface – concrete is ideal – to resist movement during forceful operation. Anchoring the pump, using appropriate bolts or a secure mounting bracket, prevents tipping and ensures consistent performance.

Consider the pump’s weight when selecting anchors. Inlet and outlet piping should be securely connected, avoiding leaks and strain on the pump body. Proper alignment minimizes vibration and extends pump life, much like optimizing system parameters. Regular checks of anchor points are vital for continued safety.

Avoiding Contamination of Water Source

Protecting water purity is paramount, akin to safeguarding system integrity against external interference. Implement a foot valve with a screen on the suction pipe to prevent debris from entering the pump. Regularly inspect and clean the intake area, removing any potential contaminants like leaves or sediment.

Avoid placing the pump in areas prone to runoff or pollution. Use food-grade materials for all components in contact with potable water. Consider a filtration system upstream of the pump for added protection, mirroring careful parameter adjustments. Proper hygiene during maintenance prevents introducing contaminants, ensuring safe water delivery.

Safe Operating Practices

Consistent, controlled operation, much like a stable system, is crucial for longevity and safety. Always prime the pump before use to prevent damage from running dry, mirroring initial system setup. Avoid over-exertion when operating the handle; smooth, consistent strokes are more effective and reduce strain.

Never operate the pump with damaged components, akin to ignoring system errors. Ensure a secure footing while pumping, preventing slips or falls. Be mindful of surrounding individuals and objects, maintaining a safe working distance. Regular training on proper operation, similar to parameter adjustments, ensures responsible use.

Future Trends in Manual Pump Technology

Innovation, mirroring system evolution, focuses on enhanced efficiency and user experience. Expect integration of advanced materials – lighter, stronger polymers – reducing pump weight and improving durability. Designs will likely incorporate ergonomic improvements, minimizing operator fatigue, similar to streamlined panel controls.

Smart features, like integrated filters and water quality sensors, could become standard. Modular designs, allowing for easy repair and component replacement, will increase lifespan. Furthermore, exploring hybrid systems – combining manual power with small-scale energy harvesting – presents exciting possibilities, akin to adjustable system parameters.

Leave a Reply

You must be logged in to post a comment.